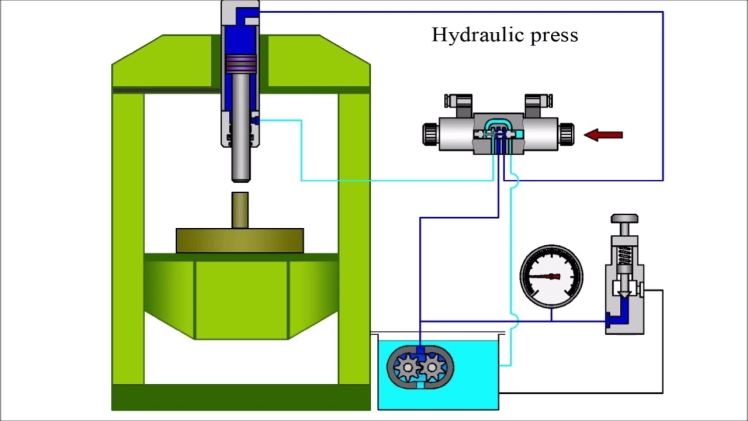

If you’ve ever been in a situation where you needed to exert tremendous pressure on an object, you’re probably familiar with the hydraulic press. Its hydraulic system uses two cylinders, one at the bottom and one at the top, to create the pressure that you need to manipulate an object in hubposts. The bottom piston moves back and forth, transferring the pressure from the hydraulic system to the upper piston, which applies the pressure that you need to apply to the object. This press is ideal for deforming high-strength steel and objects up to 20mm thick. Small repair shops also find this machine useful for performing various tasks, including assembling and repairing objects.

The hydraulic press uses Pascal’s law to determine its pressure. The principle states that pressure is equal to the force multiplied by the area in tangonews. The force that is applied to an object increases as the area increases. For example, an increase of 10 square units in area will require 10 times more force to maintain the pressure at the same level. In contrast, pressure in an incompressible fluid is transmitted equally in all directions. Moreover, unlike a static fluid, a liquid’s pressure is symmetrical throughout its volume in pklikes. As a result, changes in pressure in one area will affect the pressure throughout the entire fluid.

The hydraulic press has various types. Compared to other forms of presses, it can generate enormous amounts of force in newsforweb. Regardless of its purpose, it is ideal for large-scale industrial processes where you need to apply a lot of force. However, you should be aware of the disadvantages of hydraulic presses. This includes the risk of spills of hydraulic fluid, which can contaminate soil and groundwater below a factory. Read more about pklikes com login